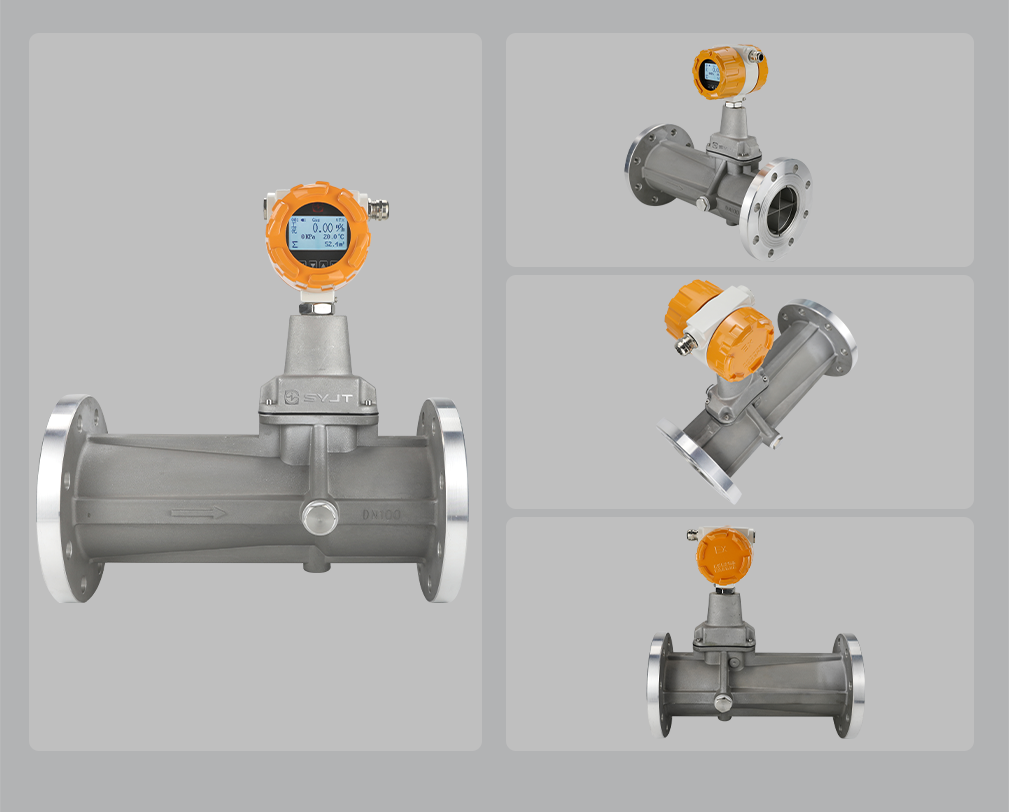

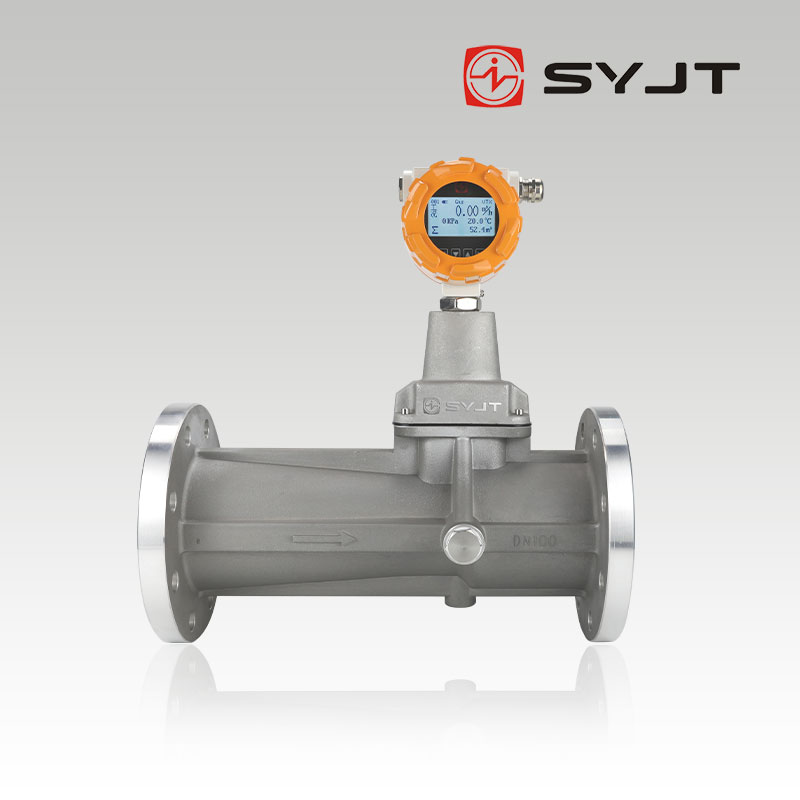

The SYJT Spiral Vortex Flow Meter is a high-precision and highly reliable flow measurement instrument widely used for measuring various gases in industries such as petroleum, chemical, power, metallurgy, and coal. The following is a detailed introduction to the upper instrument vortex flowmeter:

1、 Working principle

The flow profile of a flow sensor is similar to the profile of a Venturi tube. Place a set of spiral guide vanes on the inlet side, which force the fluid to generate intense vortex flow when it enters the flow sensor. When the fluid enters the diffusion section, the vortex flow is subjected to backflow and begins to undergo secondary rotation, forming a gyroscopic vortex precession phenomenon. The precession frequency is directly proportional to the flow rate and is not affected by the physical properties and density of the fluid. By measuring the secondary rotation precession frequency of the fluid with the detection element, good linearity can be obtained over a wide range of flow rates. The signal is amplified, filtered, and shaped by a preamplifier into a pulse signal proportional to the flow rate, and then sent to the microprocessor for integration processing along with temperature, pressure, and other detection signals. Finally, the measurement results (instantaneous flow rate, cumulative flow rate, temperature, pressure data) are displayed on the LCD screen.

2、 Main features

No mechanical movable parts: The flowmeter has no mechanical movable parts inside, so it is not easy to corrode and has the characteristics of stability, reliability, and long service life. Long term operation does not require special maintenance.

Intelligent integration: The intelligent flowmeter integrates flow probes, microprocessors, pressure, and temperature sensors into one, adopting a built-in combination with a compact structure. It can directly measure the flow rate, pressure, and temperature of fluids, and automatically track and compensate for compression factors in real time.

High precision and high repeatability: Advanced detection technology is adopted to ensure that the measurement has high precision and high repeatability.

Strong anti-interference ability: Adopting dual detection technology can effectively improve the strength of detection signals and suppress interference caused by pipeline vibration. At the same time, advanced domestic intelligent seismic technology is adopted to effectively suppress interference signals caused by vibration and pressure fluctuations.

Intuitive display: Using a Chinese character dot matrix display screen with multiple digits, the reading is intuitive and convenient. It can directly display the volume flow rate under working conditions, the volume flow rate under standard conditions, the total amount, as well as parameters such as medium pressure and temperature.

Multiple output modes: The converter can output frequency pulses, 4-20mA analog signals, and has an RS485 interface, which can be directly connected to a computer for a transmission distance of up to 1.2km.

Low power consumption and multiple power supply methods: The whole machine has low power consumption and can be powered by built-in batteries or external power sources.

3、 Application Fields

The upper vortex flowmeter is widely used in multiple industrial fields, especially for measuring various gases, including natural gas, coal gas, steam, etc. In the oil and gas industry, it is used to measure the flow rate of fluids such as crude oil and natural gas, providing important data support for energy production and distribution; In the chemical industry, it is used to measure the flow rate of various corrosive or high-temperature and high-pressure fluids to ensure the stability and safety of the production process; In the water treatment industry, it is used to monitor the flow changes of urban water supply, sewage treatment and other links, providing a basis for water resource management and scheduling; In the food and pharmaceutical industry, it is used to measure the flow rate of liquid raw materials, semi-finished products, and finished products to ensure product quality and production efficiency.

4、 Installation and maintenance

When installing flow meters, certain specifications and requirements should be followed, including strictly prohibiting direct welding at the inlet and outlet flanges, cleaning the pipeline to remove debris, and installing in places that are easy to maintain and have no strong electromagnetic field interference. At the same time, the leakage situation at the flange of the flowmeter should be checked regularly to ensure the normal operation of the flowmeter. During pipeline pressure testing, attention should be paid to the pressure measurement range of the pressure sensor equipped on the intelligent flowmeter to avoid damage to the pressure sensor due to overpressure.

In order to maintain the long-term accuracy and reliability of the flowmeter, regular maintenance and inspection are also necessary. This includes checking whether the display and data recording functions of the flowmeter are normal, cleaning the measuring chamber of the flowmeter (if necessary), replacing the battery (if using a built-in battery), and checking the instrument coefficient and lead seal.

In summary, the vortex flowmeter with high precision, high reliability, wide range ratio, and intelligent design has broad application prospects and important value in the field of flow monitoring.

Links

Links